Timeless Beauty: Chicago Landmark Restored to Its Natural Stone Glory

All photos unless otherwise specified appear courtesy of the Richard H. Driehaus Museum Archives.

After the 1871 Great Chicago Fire, many homes made of wood were destroyed. When it came time to build new homes, laws were passed to prevent a similar disaster. Fireproof materials such as brick, marble, limestone, and terracotta tile became the preferred building materials since constructing buildings with wood was banned in the downtown area.

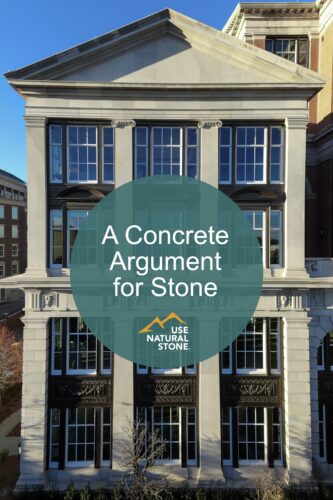

Eight years after the fire, construction of the Nickerson House on Chicago’s near northside neighborhood began. The three-story, 24,000 square foot Italianate mansion was reported to be the largest and most extravagant private residence in Chicago at the time it was completed. The exterior façade is made of limestone and Berea sandstone from Ohio. Known as the “marble mansion,” the property is even more impressive inside. “The interior stonework consists of at least 17 different types of French, Italian, Belgium, and American marble as well as onyx and alabaster,” says Sally-Ann Felgenhauer, director of collections and exhibitions for The Richard H. Driehaus Museum.

Soon after it was built, the light-gray sandstone exterior would lose its luster due to environmental issues. “Over the years, the naturally light stonework blackened due to the build-up of soot and grime from industrial pollutants,” Felgenhauer says. As the exterior became dark and unsightly, the decorative stone elements also began to erode.

The Nickerson House became The Richard H. Driehaus Museum when Richard H. Driehaus, a Chicago investment manager well known for his interests in preserving historic buildings, bought the home in 2003. According to a New York Times article, Driehaus purchased the home from the American College of Surgeons, a professional association that had owned it since the 1920s and soon afterward hired M. Kirby Talley Jr., an Amsterdam-based author and art historian, to oversee the restoration.

“My marching orders were to take it back to 1883,” Talley says in the New York Times article. “It’s remarkable to find a situation like this where you can honestly say that no expenses were denied to do the job the right way.”

In 2003, the same year Driehaus acquired the property, major restoration of the building began, including restoring the exterior façade.

Restoration of a Historical Landmark

“The Driehaus Museum as a Gilded Age mansion is an important piece of Chicago’s history and a window into the past that looks forward by exploring the interplay between historic and contemporary art that honors the legacy of Richard H. Driehaus,” Felgenhauer says.

Restoring the exterior required careful work by skilled teams. According to Felgenhauer, none of the stonework has been changed, but it has been restored.

The sandstone and limestone used were both native materials to the Midwest. Berea sandstone, quarried in Ohio, was a common choice for buildings. Sandstone is a soft and porous material and while fireproof, would eventually absorb the soot billowing from the smoke from nearby coal plants. By the time Driehaus purchased the property, “those industrial pollutants had morphed into a kind of 100-year-old crust. In some places, that crust was 20 millimeters thick,” according to the Driehaus Museum blog post on why the Nickerson House used to be black.

“During the restoration, the Driehaus Museum contracted the Conservation of Sculpture & Objects Studios, Inc. (CSOS) to clean the façade using handheld lasers through a process called ablation,” Felgenhauer explains. “They removed 20,000 square feet of black crust from the stonework over a period of 18 months between 2004-2005. This was officially the first building to be cleaned in North America using this process.”

The reason lasers were used instead of more aggressive approaches such as micro-blasting was because the exterior was so soft that a harsher process would have resulted in worsening of the erosion and in some cases bleaching out the sandstone’s natural yellowish color.

According to the Driehaus Museum website covering the natural stone exterior restoration project, the laser cleaned at a rate of approximately 2.5 square feet per hour.

The website shares a bit more detail on the process of using the laser. “A beam of light from a handheld contraption is pointed at the building, and it breaks the molecular bond that had formed between the stone and pollutants,” according to Driehaus Museum.

According to Felgenhauer, the CSOS team spent more than a year clearing 20,000 square feet of black crust and it was all done with small handheld instruments.

The building was added to the National Register of Historic Places in 1976 and designated a Chicago landmark on September 28, 1977. In 2008, the Commission on Chicago Landmarks awarded the Richard H. Driehaus Museum with the Chicago Landmark Award for Preservation Excellence, Felgenhauer adds.

Keeping Natural Stone Looking Great

While the restoration project was completed in 2004, the museum continues regular maintenance which includes restoration and conversation. “More recently, as part of the museum’s maintenance program, the building façade underwent tuckpointing,” says Felgenhauer.

It’s a testament to its longevity that with proper upkeep and maintenance, natural stone can withstand even the harshest elements and last for centuries.