Using Locally Sourced Limestone to Add Structure and Strength to Historic Preservation Projects

Julia Manglitz, AIA, LEED AP, APT RP, has worked on several building types throughout her career: county courthouses, state capitols and office buildings, university campus halls and community centers. What makes each of these public buildings unique is they’re all landmarks in their communities. Another thing each of them has in common? Almost all feature locally or regionally-sourced natural stone.

Manglitz began her work in Kansas, where limestone is plentiful. As a result, most of the older heritage and iconic buildings showcase local limestone. The featured projects were completed during her tenure as an associate principal of historic preservation at TreanorHL. She recently transitioned to senior architect with Quinn Evans.

Manglitz assessed sixty stone buildings on the Kansas State University campus in the summer of 2019. The buildings ranged in age from 20 to 143 years old; the study identified life-safety and water infiltration issues to help the University prioritize and plan façade repairs. Holton Hall (pictured here) was constructed in 1900 using Kansas Cottonwood and Junction City limestones. Photo credit TreanorHL.

Stone is one of the original regional materials

As an architect focused on historic preservation, Manglitz works with natural stone often. Stone has been used often throughout history for its durability and because it is fireproof. Manglitz notes that natural stone structures were also lower maintenance than wooden structures that required frequent repainting.

As westward expansion began and immigrants from Germany, Sweden, Italy, England, and Ireland settled in or passed through states like Kansas, many brought with them a history of stonework and masonry. An abundance of usable stone in relatively modest sizes available in quarries throughout the Midwest made it easy to source and use.

“There were various times of groups moving through. Some settled, some kept moving, but there were generally people around who understood what good material looks like, how to get it out of the ground, and how to get it shaped and put into buildings,” Manglitz says.

The case for regional natural stone

Kansas is known for its limestone. Manglitz notes that one of the most well-known stones is Cottonwood limestone, a light gray-to-cream-colored fine-grained limestone. Cottonwood is the main facing material for many buildings on the University of Kansas and Kansas State University campuses as well as much of the Kansas State Capitol.

Another local stone is Silverdale, a creamy limestone with gold color tones often used in split face veneer stone applications and cut limestone applications due to its tight grain and lack of holes or pits.

“One of the more interesting stones that we run into a lot at Kansas State University is something called Neva, which is a slightly higher density limestone,” Manglitz adds. “It’s good for rough ashlar work and rock faced finishes.”

Neva is often mixed with Cottonwood, which is softer and can take a tooled finish.

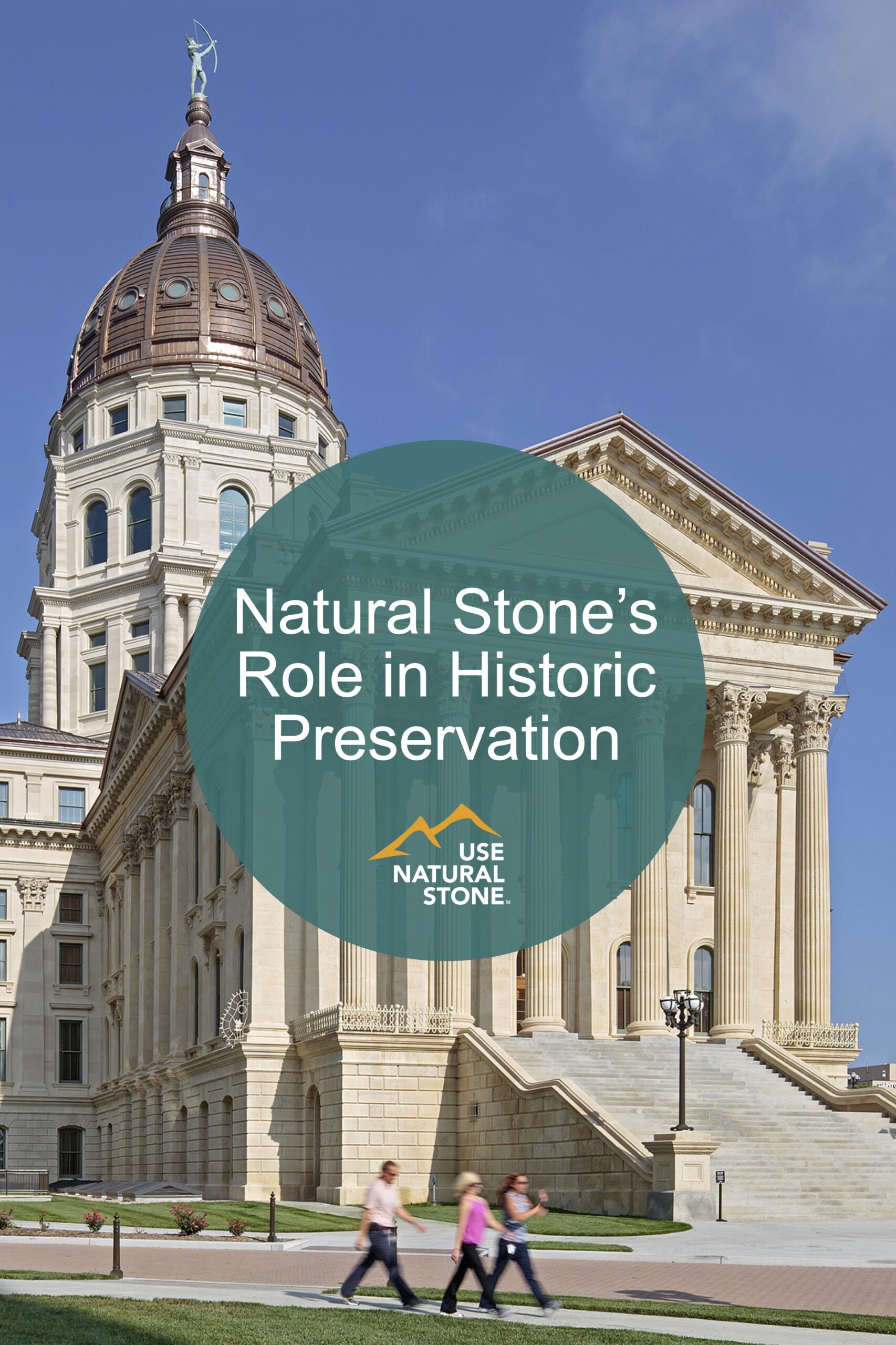

The Kansas Statehouse exterior masonry restoration, completed in 2011, required over 7,000 dutchman repairs varying in size from a few pounds to several thousand. The façade features four types of limestone and seven granite, dating from the original construction to subsequent repairs. The project received a 2018 Tucker Design Award. Photo credit Aaron Doughtery/TreanorHL.

Historic preservation and natural stone

While limestone is readily available throughout the Midwest, Manglitz notes sourcing can still be challenging for historic preservation projects, since blocks are not always actively quarried in the same size that were originally used on a building.

- Fire gutted Kansas State University’s Nichols Hall in 1968. Adaptively reused in 1985, the 1911 building has continued to suffer accelerated deterioration of Neva and Cottonwood limestone due to the heat damage from the fire—a portion of the south façade before repair and stone replacement. Photo credit TreanorHL.

- The stone façade of Nichols Hall as it appeared in 2017 after stone repair, replacement, repointing, and cleaning. Cottonwood limestone, supplied by Lardner Stone, was used when replacement was necessary. Photo credit Architectural Fotographics/TreanorHL.

“Trying to get material in the size that you would like to get it can be a pretty important part of sourcing the stone,” she explains. “When we’re working in preservation, that’s really dictated by the existing building. When we have to go out looking for substitute materials, or substitute stones, it does get really challenging.”

In some cases, Manglitz is trying to match the original color on a building. Other times, she’s looking for a stone that can work with a particular finish. “A lot of the buildings that I work on have some sort of tooled finish to them or they have carvings incorporated, and trying to make sure that you can accurately replicate and get the same feel for it is important,” she says.

OK State: From 2016 to 2020, Manglitz was the project manager for exterior masonry repairs to the 1917 Oklahoma State Capitol. The restoration included replacing veneer panels, dutchman repairs, crack pinning and injection, cleaning, and repointing. Tishomingo pink granite from Oklahoma clads the first floor, and Hoosier silver-gray from Indiana Quarries the upper floors. Photo credit F. Stop Photography/TreanorHL.

Victory Eagle connects with University of Kansas campus

Manglitz works to recommend stone based on everything from price to aesthetics. She and her team were called upon to work on a 1929 “Victory Eagle” statue in honor of Douglas County residents who lost their lives fighting in World War I. The bronze Victory Eagle monument features a mother eagle with her wings spread wide, defending her eaglets in a nest.

The statue had seen better days after being stolen and thrown in a ditch before being rescued in the early 1980s. A new base needed to be designed before it could be relocated to Memorial Drive with other war memorials. The client initially wanted a base that wasn’t a native Kansas stone, but Manglitz recommended other stones that would be a more appropriate fit.

Victory Eagle: The 1929 bronze sculpture, Victory Eagle, moved to a new home along Memorial Drive at the University of Kansas in 2019. The stone pedestal follows the pattern historically recommended by the Victory Highway Association, which organized the memorials in 1921 to commemorate the loss of life in World War 1. Silverdale limestone, quarried in southern Kansas, and Mountain Green granite from Coldspring form the pedestal. Photo credit Julia Mathias Manglitz.

She began by recommending granite for the first two courses. “Granite is going to hold up a lot better; it’s not going soak up de-icing salts that are likely to be used on the sidewalks and it will handle that installation much better than limestone,” she shared, adding that the dark green granite from Coldspring goes well with the overall landscape, since it sits on a site looking down into a forested valley.

The main shaft is Silverdale limestone from Kansas. “Silverdale has a little bit of a warmer color and it tends to go better with the existing architecture,” she says, again emphasizing the importance of regional stone used on other buildings throughout the area. “The more locally sourced stones historically used on the campus have a slightly warmer tone to them.”

Manglitz sees many benefits to choosing locally sourced stone over manmade materials like precast concrete in her work. She points to the lower embodied energy inherent in natural stone when compared to precast concrete as a major factor. “Precast you can do anywhere,” she says. “When you’re using a local stone product, you’re linking yourself to the history of construction within your particular region. It’s partly about place-making. It’s partly about the environment. And it’s partly thinking about durability for the next generation.”