Dakota Mahogany: Core of the Continent

Note: This article is part of a series about American quarries. If you work for a quarry that’s a member of the Natural Stone Institute and you’d like your quarry to be featured here, contact Karin Kirk. Thank you!

Continents don’t come of age all at once. Rather, they are assembled, piece by piece, through the long process of plate tectonics. Every continent has a core—or a ‘craton,’ as geologists call it – that serves as its original landmass.

Onto this nucleus of a continent, new land carried along by plate tectonics eventually bumps into the craton, and becomes part of the new continent, growing it larger through successive collisions. Thus, most continents are oldest in the middle, with progressively younger parts added around the edges.

Onto this nucleus of a continent, new land carried along by plate tectonics eventually bumps into the craton, and becomes part of the new continent, growing it larger through successive collisions. Thus, most continents are oldest in the middle, with progressively younger parts added around the edges.

North America was “born” about 3 billion years ago with the assembling of the Superior Province, which makes up the bedrock in south-central Canada and north-central United States. A sequence of five events each added a new piece of land, as the young continent gained the real estate that became Manitoba, Ontario, the Great Lakes Region, and northern Minnesota. The youngest part of the original North American craton is called the Minnesota River Valley terrane, which is a chunk of land that slid into the young North American continent around 2.6 billion years ago. At the time of this tectonic collision, Minnesota and the Dakotas were home to soaring mountain ranges as landmasses collided and pushed rocks upward.

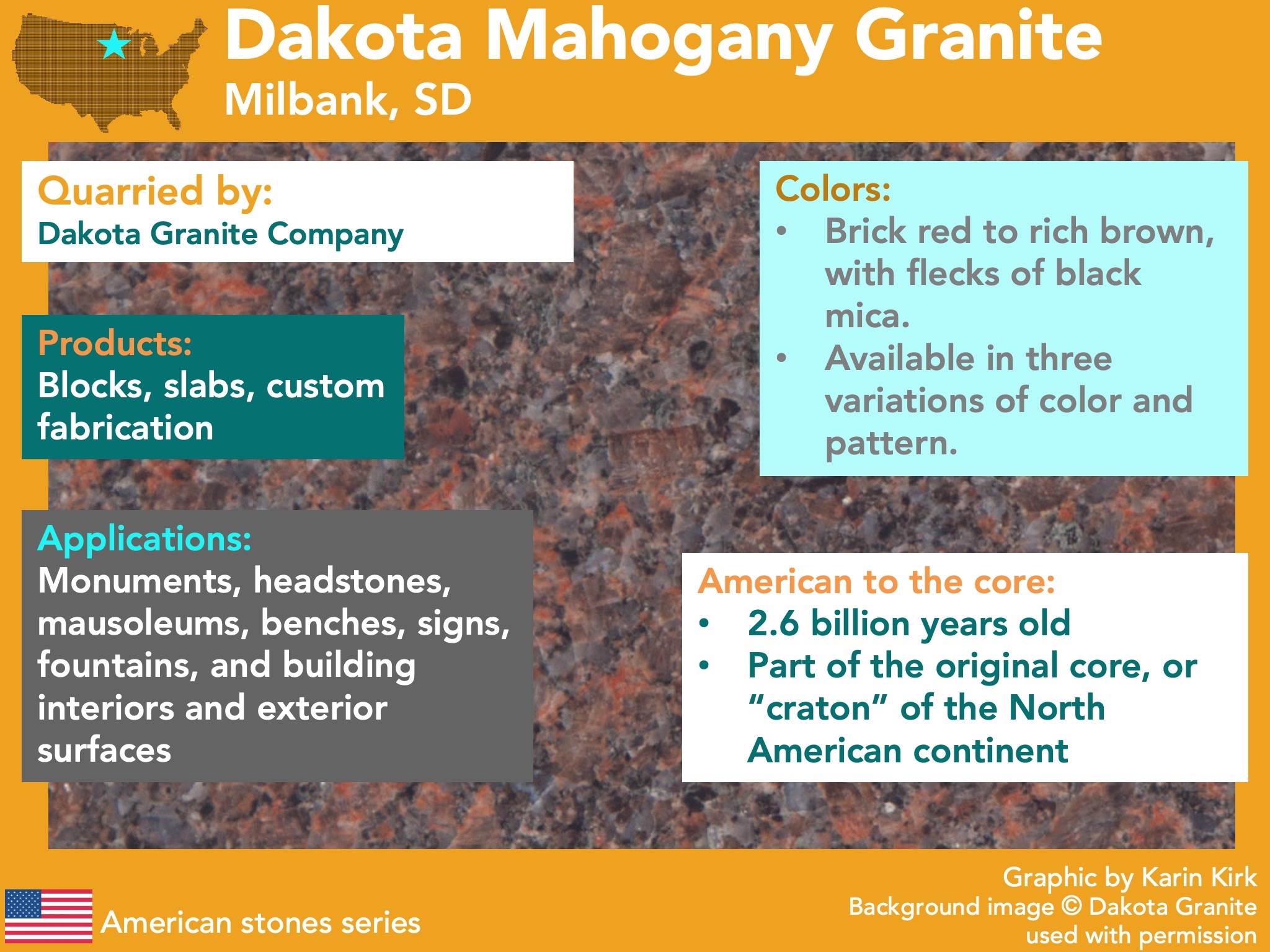

Pressure and heat from the tectonic activity caused the bedrock to buckle and melt, creating liquid magma. Pockets of molten rock flowed upward within Earth’s crust, but didn’t reach the surface, so the magma didn’t erupt like a volcano. Instead, these magma pools cooled slowly while still underground, forming crystals of feldspar, quartz, and dark mica. Western Minnesota contains several of these granite intrusions, and because geology has no concern for state lines, one lone spot of granite welled up in South Dakota, not far from the Minnesota border. This was the birth of the Dakota Mahogany Granite, in what is now Milbank, South Dakota.

The formation of Dakota Mahogany marks the last time the Midwest endured a tectonic collision. Since then, seas have advanced and retreated across the landscape, the continents have rearranged themselves in different parts of the globe, and vast ice sheets grew, then melted, then grew again, over the course of several ice ages. After 2.6 billion years of erosion, the Midwest’s former mountain ranges have been worn down, leaving the landscape mostly flat. Through all of this, Dakota Mahogany sat patiently, waiting for its day in the sun.

In 1925, the Dakota Granite company was incorporated, and the stone began its second life.

“The Benchmark for Brown Granites”

The trademark color of Dakota Mahogany has become recognizable around the world. It’s made of three minerals: brick red feldspar, grey smoky quartz, and black biotite mica. Taken together, the rich colors lend a deeper, weightier color than the light grey, tan, or pink hues that are more common for granite. The feldspar and quartz crystals are large enough to sparkle in the sun, and the stone holds a high gloss polish that will shine for decades.

Rick Dilts is the Marketing and Sales Manager at Dakota Granite. “Dakota Mahogany is kind of the benchmark of brown granites,” he says. “I think it’s been around longer than just about any other brown granite. You go anywhere in the world and you’ll find Dakota Mahogany from Milbank, South Dakota.”

Dakota Mahogany is primarily used for memorials—which can encompass everything from a simple headstone to intricately carved monuments, mausoleums, and customized designs that celebrate and honor the memories of our loved ones.

For a stone as old and persevering as Dakota, a memorial seems like the perfect application. “Just the longevity of it,” says Dilts. “You look at concrete and how long that lasts compared to stone. Stone may cost a little bit more but in the long run it’s going to cost much less if you use a natural product like stone.” He muses, “Just look at the pyramids and consider how long they’ve been there.”

Expanding the Palette

Dakota Granite has been evolving and expanding, both in terms of the stone they quarry as well as how their stone is used. Beginning in the 1960s, the company started selling Dakota Mahogany blocks overseas, largely to Japan. Dilts recalls, “I was flying to China one year and walked into the restroom at the Narita airport, and from floor to the top of the walls were Dakota Mahogany. It was really cool to see that.”

Dilts continues, “In about 1990 we purchased a couple more quarries,” including another quarry that was already tapped into Dakota Mahogany, and a granite quarry just over the state line in Bellingham, Minnesota.

In 2021, Dakota Granite was bought by the same company that owns Kasota Stone, and the two became sister companies. This allowed Kasota’s stones to become part of the palette of Dakota’s offerings and vice-versa.

But the relationship runs deeper than simply selling the same stones; both companies share a business philosophy called the Entrepreneurial Operating System. Two managers from Kasota have moved over to Dakota to help grow the business: Jake Barkley and Colin Kimball. To say that Barkley and Kimball have passion for their work is an understatement. The pair appear to radiate energy and drive, especially as they play off each other and Dilts as they describe their roles in the company and plans for the future.

Kimball describes his job as “The Integrator,” as he ties together the people and departments throughout the company. “I’ve learned a lot from a lot of really great people,” he says. “And I’m proud to be a part of a big team out in Milbank.”

Barkley is the visionary – planning the broad strategy and direction. “My role is basically to set the course or the vision for the company,” he says.

The management team is sharply focused on growth, but not simply for growth’s sake. Every business decision centers around the company’s core values. A key component of this strategy is to invest in and empower their employees. “As you start to center your culture around core values, it helps attract talented people to come work with us,” says Barkley. “It helps us coach our people as well.”

The “Wow” Factor

A focus on people is an especially wise practice in a rural location, where hiring and retaining employees can be an ongoing challenge. “It’s a very rural community so Dakota Granite is one of the larger employers,” says Dilts.

Milbank has a population of around 3,500 people and is two hours from the nearest commercial airport. In this region, one can’t simply hire workers with specialized skills—the workforce needs to be cultivated over time.

Dilts explains, “We don’t live in one of the granite centers of the country. So we pretty much have to train everybody. We’ve been lucky enough to find a few hand polishers that came from the countertop industry. But as far as stonecutters go, I don’t know if we’ve ever found somebody with that experience.”

This is where the company’s people-centered approach gives them a leg up on hiring. Dilts observes, “We’ve got a really good reputation for how we treat our employees and I think that’s helped us draw in a lot of excellent people and retain them.” He continues, “We have one family, their fifth generation is working here now. Isn’t that amazing?”

Dakota Granite has a staff of around 93 workers, working year-round in the quarries, as well as in the cutting, carving, and polishing of finished pieces. Production work is done part by machine, and part by hand, and the company pairs high-tech CNC machines with timeless handwork.

Kimball appreciates the contrast between humans and machines. “We have a robot that can make these beautiful parts. And then we have true artisans that are making really beautiful parts by hand. To see the progression from what people can do by hand and what we can do with a piece of equipment is amazing. It’s fun to be a part of.”

Barkley confirms that skilled handwork is irreplaceable: “Yeah, a lot of the hand cutting with hammer and chisel has to happen by hand to get a beautiful finish. It’s a special thing. You can’t replicate it.”

“There’s something extremely rewarding for people when they finish a beautiful part,” says Kimball. “I see guys and gals taking pictures with their phones of the work that they did.” Working with stone invokes a sense of permanence that can be hard to find in an era where too much seems disposable. Kimball derives deep satisfaction not just for himself, but for his employees: “To be proud of what you do at work every day and to know that you’re a part of something that’s gonna last for hundreds of years.”

“There’s so much ‘wow factor’ in our plant and our quarry,” says Dilts, echoing Kimball’s pride. “But watching the stonecutters is a big highlight for me. It’s just so fascinating to watch those guys hit that chisel with their hammer every time and not their hand.” Dilts laughs, continuing, “I’ve tried it. That doesn’t work very good for me.” Barkley and Kimball join in the laughter as Dilts continues, “But you know, the team is so good at what they do. It’s just so fun to watch them.”

Bright-eyed Planning for the Future

As Dilts, Kimball, and Barkley look ahead, they’re helping the company expand its focus into architectural work, including municipal projects and outdoor spaces.

Barkley describes a current focus on landscape stone. Dakota’s current projects include “substantial outdoor infrastructure” where people can “walk in and around park-like spaces and get up close and personal to the stone,” say Barkley. He notes that the use of natural stone in outdoor spaces is a trend that’s been gaining momentum.

Even the most inspired designs can still get bogged down in today’s business environment, and Kimball explains how planning ahead is more important than ever. “On the back end of the pandemic it’s changed a lot of our behavior and our strategy. You used to be able to pick up the phone and get a few spare parts quickly from Amazon.” Supply chain bottlenecks, shipping delays, and staffing shortages have changed the nature of project management. “We’re doing a lot more in-depth planning. We’re preparing more for the future. We’re having more conversation around what potential pitfalls are around the next corner. I think it’s changed our behavior in a positive way. We now take a more realistic look at some of the obstacles that may occur and how to overcome them when we run into them.”

The company’s local quarries offer a simple, domestic supply chain that keeps lead times short. In a competitive marketplace, “perhaps our shorter lead times and the availability of our products are what’s helping fuel our growth,” says Barkley. “Some of our customers are getting quotes for lead times that are three or four times what ours is. I think that is leading to some pretty substantial order increases.”

Dakota Mahogany has been waiting 2.6 billion years for the right opportunity. The quarry is in good hands, with stewards who are eager to shepherd the stone to its best use. “We’re in a pattern of what I would consider extreme growth,” says Barkley. “We’re going to continue to grow this business until the next hurdle arrives. Then we’ll solve that problem, whatever it is.”