Sifting Through the Confusion about Manmade Quartz Surfaces

Note: A version of this article appears in the Spring 2019 issue of Building Stone Magazine.

We are living in the age of information. In the palms of our hands, we can tap into an enormous realm of facts, opinions, advertisements, and educational materials. However, because information is so easy to access and share, plenty of not-so-great material gets widely circulated, too. Our challenge is to sort fact from fiction, to educate ourselves, and guide designers, architects, and customers through the melee.

The countertop industry is a big one, offering billions of dollars in annual sales in the United States alone. Naturally, competition is fierce as various companies vie for attention and make bold claims to lure customers. Quartz countertop manufacturers are working hard to influence the marketplace, and they are doing so with big promises and lofty assertions. As with all information, it’s important to pause and reflect on the validity of these statements so that we can make informed choices.

What’s In a Name?

Companies that manufacture quartz countertops have been very clever with their naming. The word “quartz” represents one of Earth’s most abundant minerals. One well-known brand of quartz surfaces says that their product is “pure natural quartz.” The phrase admittedly has a nice ring to it. But how accurate is it?

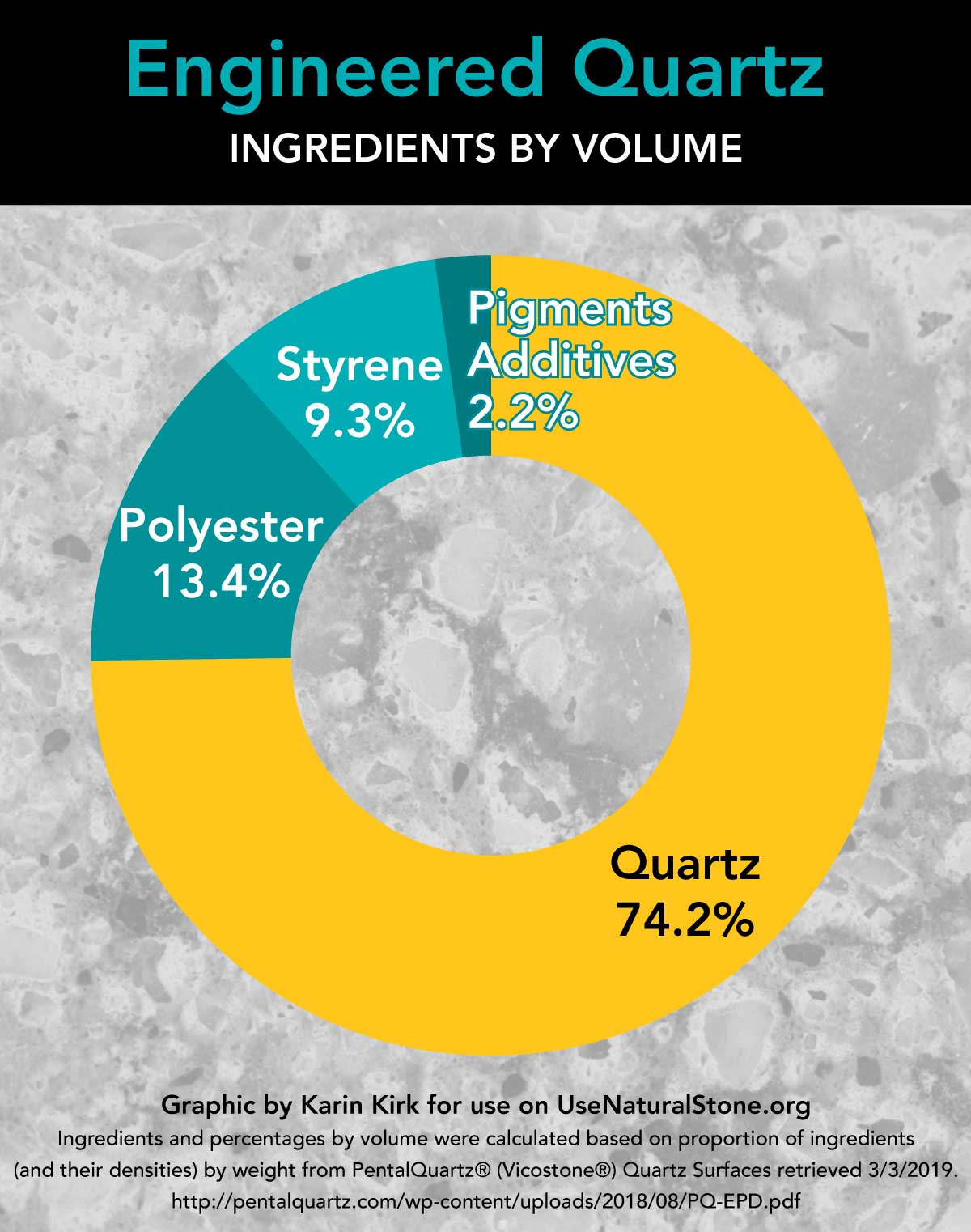

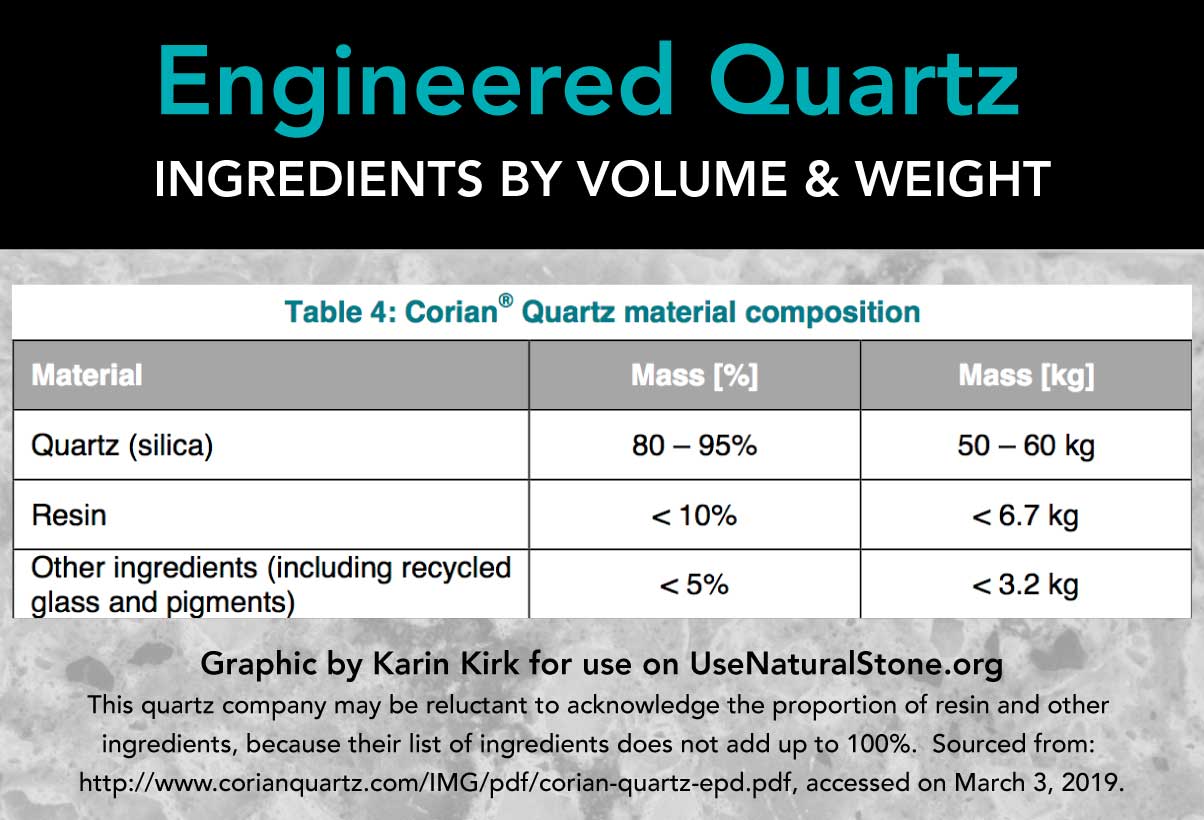

Geologically speaking, a manmade quartz countertop is not pure natural quartz. The only thing that fits that criterion is quartzite, which truly is pure natural quartz. Manufactured quartz surfaces are mostly quartz, but they are not purely quartz. Depending on the brand and the color, manmade quartz surfaces are 70% to 93% quartz sand or aggregate, mixed with polyester resin, ethenylbenzene (also known as styrene), pigments, and other additives.

Is Engineered Quartz the Same as Natural Stone?

I believe another area of confusion arises when quartz manufacturers refer to their products as natural stone. For example, one paragraph of a quartz company’s website begins: “All natural stone surfaces, including [company name]….” This type of phrasing is prevalent throughout the company’s marketing materials. In other examples, they say that they sell the world’s “most beautiful and innovative natural stone surfaces,” they “offer the world’s finest natural stone countertops,” and they describe their products as “stone slabs.”

From my perspective as a geologist and a professional admirer of rocks, I can easily appreciate the attempt to align a manmade product with a natural one. We can all agree that natural stone is awesome. But manmade quartz isn’t natural stone. It’s a bit brazen to say that it is.

For the record, natural stone is both naturally occurring and made out of stone. Granite, limestone, quartzite, and marble are all natural stones. They form in nature, and only in nature. They are made of minerals, and only of minerals. Feldspar, quartz, hornblende, hematite, garnet, calcite, muscovite: these are the ingredients in nature’s pallet. You’ll find no polyester resin on a seafloor, nor ethenylbenzene in a magma chamber—thank goodness.

Will the Real Mont Blanc Please Stand Up?

Mont Blanc quartzite (right) a natural stone, is often imitated by manufactured quartz producers. Notice the inherent difference of one manufacturer’s Mont Blanc (left) and a second company’s Montblanc (center) as manufactured quartz product offerings compared to its natural counterpart. Photos supplied by Slabworks of Montana and Triton Stone.

Stroll through a retailer that sells paint, tile, stone, or anything else that comes in colors and flavors, and you’ll encounter an amusing selection of names for colorways. Customers face a staggering array of choices as they work through the details on new construction or remodels, and at times the decisions can feel paralyzing. Should your clients opt for Cloud White or Dune White for their trim color? Should the grout be Bleached Wood or Urban Putty?

As for the countertop, should they choose Mont Blanc, Mont Blanc, or perhaps Montblanc? Continuing the theme of copying natural stone, several quartz companies have usurped individual stone names and applied the exact same label to their manmade products. The original Mont Blanc is a genuine natural stone: a white quartzite with light grey layering. Mont Blanc is also the name of a slightly speckled pale grey manufactured product of one quartz producer. Montblanc is also a white and grey “marble-look” from a second quartz producer.

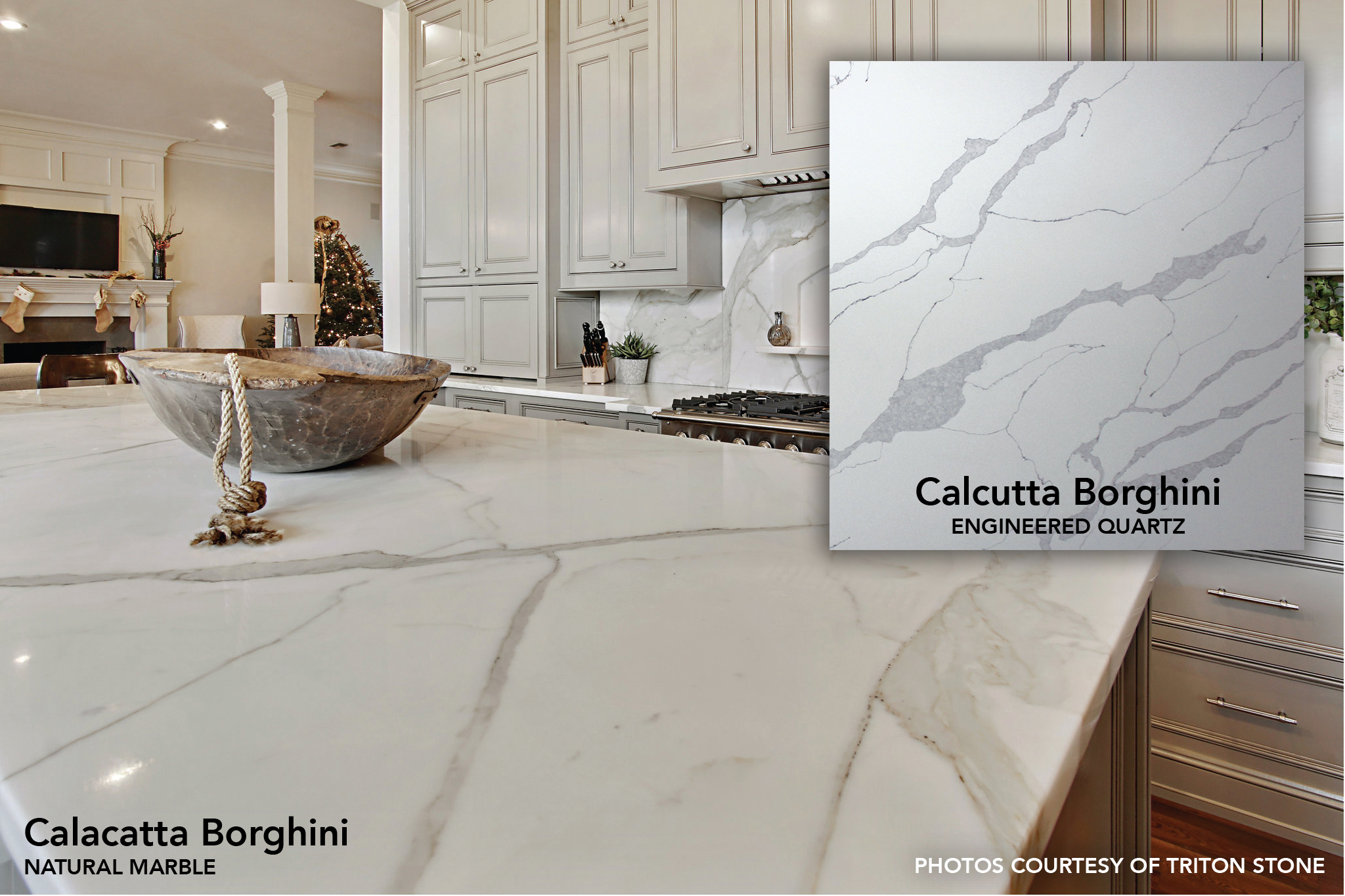

Some quartz product names intentionally evoke natural stone, such as this manufactured quartz offering called Calcutta Borghini (inset image), factory created and similarly named to compete with Calacatta Borghini marble, shown installed in this kitchen. Photos courtesy of Triton Stone.

This practice is widespread. Some quartz product names intentionally evoke natural stone: Capri Limestone, Charcoal Soapstone, Onyx Carrara, Calacatta Nuvo. Other cases are even bolder, taking the identical names from well-known stones and applying them to manmade versions. Super White, Taj Mahal, Emperador, Thassos, Nuage, and Statuario are all popular, prestigious natural stone, but they are also the names of synthetic countertops. How about Piatra Grey versus Pietra Grey? Do you know which one is real stone and which is an imposter?

I suspect that most in our industry can empathize with the potentially confusing choice designers and customers need to make. The best we can do is to help guide clients toward options that meet their needs, while providing education about different types of products. But when companies deliberately muddy the water and intentionally confuse their customers, it makes life harder for all of us.

Granite Comes From the Earth

Naming aside, what are the practical differences between manmade quartz products and genuine natural stone? Let’s start by looking at how each one is formed.

A perpetually popular natural stone for countertops is granite, an igneous rock that was once molten magma. Magma occurs throughout the Earth’s crust: under volcanoes, along seams between tectonic plates, and in hotspots.

The texture of granite sheds light on its past. Magma that cools relatively quickly will have small and uniform crystals. Deep magmas cool more slowly. In the process they grow beautiful, large minerals with complex shapes that are evocative of their internal atomic geometry. Granites with super large minerals, called pegmatites, form when there is some water mixed with the magma, which spurs minerals to take shape more readily.

In all cases, the rock turns from liquid to solid over a span of thousands to millions of years, and takes shape miles deep within the Earth’s crust. These inexorably slow geologic processes forge a stone that is dense, durable, and will far outlast our lifetimes. Thanks to variations in the composition of the magma, granite comes in a span of all-natural colors, from nearly white, to coppery brown, to deep grey and black. Patterns range from mild to wild, with aesthetic variations to suit all styles and tastes. Each piece of natural stone is unique and each bears the mark of a particular time and place in our planet’s history.

Manmade Quartz Comes From a Mold

Manufactured quartz slabs are composed of three main ingredients: particles of mineral quartz, resins, and pigments. The quartz particles can vary in size from about 5 millimeters down to less than half a millimeter. Polyester resin binds the mineral pieces together. In some cases, the resin is mixed uniformly through the slab, and in other cases there are visible areas of resin, depending on the design. The same is true of pigments; some designs are the same color all the way through, while others have ribbons or accents of different hues, which are often meant to imitate the naturally occurring patterns in natural stone.

Manufactured quartz slabs are made by blending the ingredients, then pouring the mixture into a mold. Different manufacturers use different processes, but some combination of vibration, compaction, heat, and a vacuum are applied to cure the slabs from a slurry to a solid.

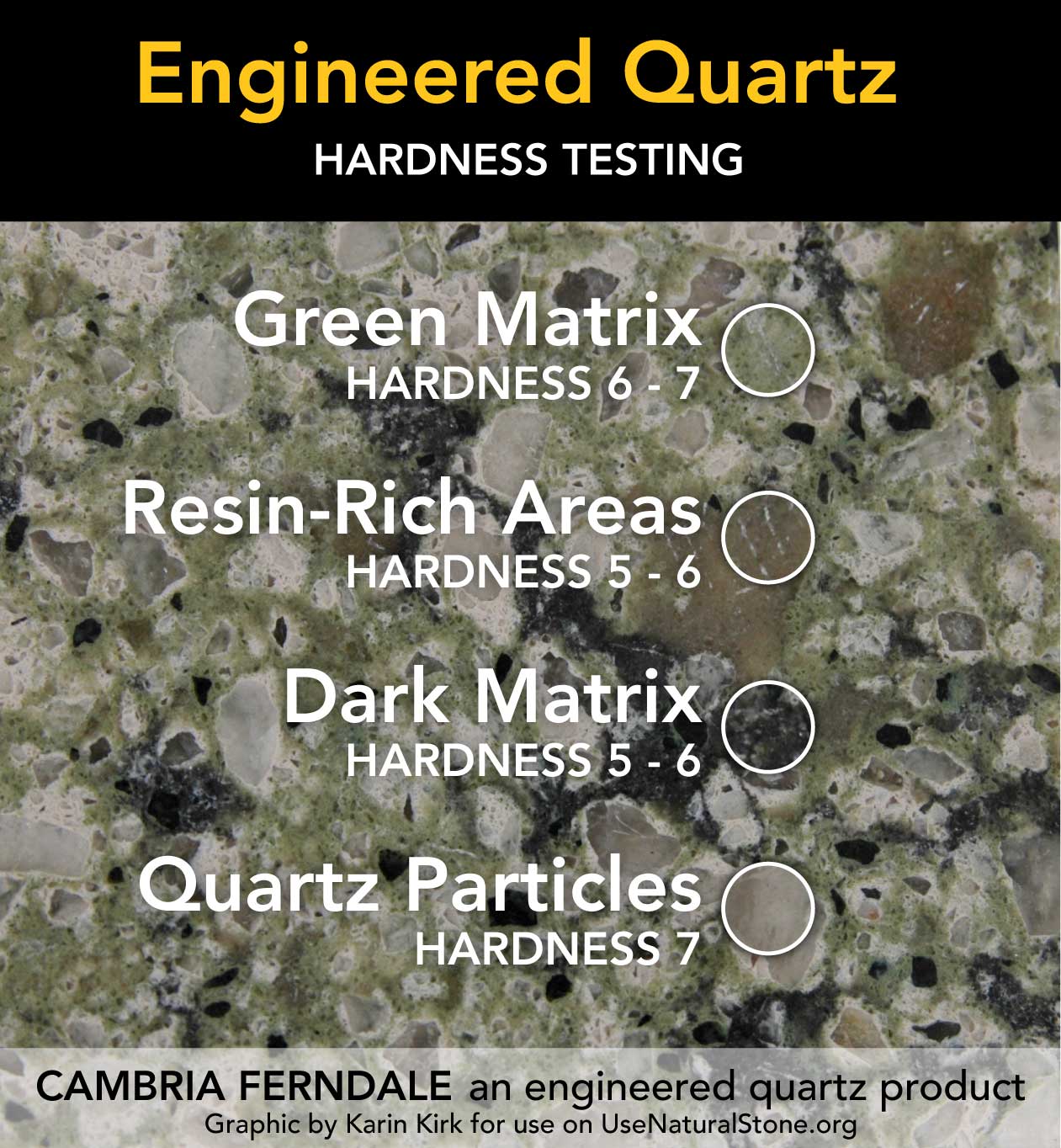

Testing the Hardness of Quartz Slabs

The website of a major quartz manufacturer makes this statement about the durability of its product:

“[Company name] is much harder than granite or marble making it more durable. That means [company brand] is less likely to scratch, chip, or stain for years of worry-free service.”

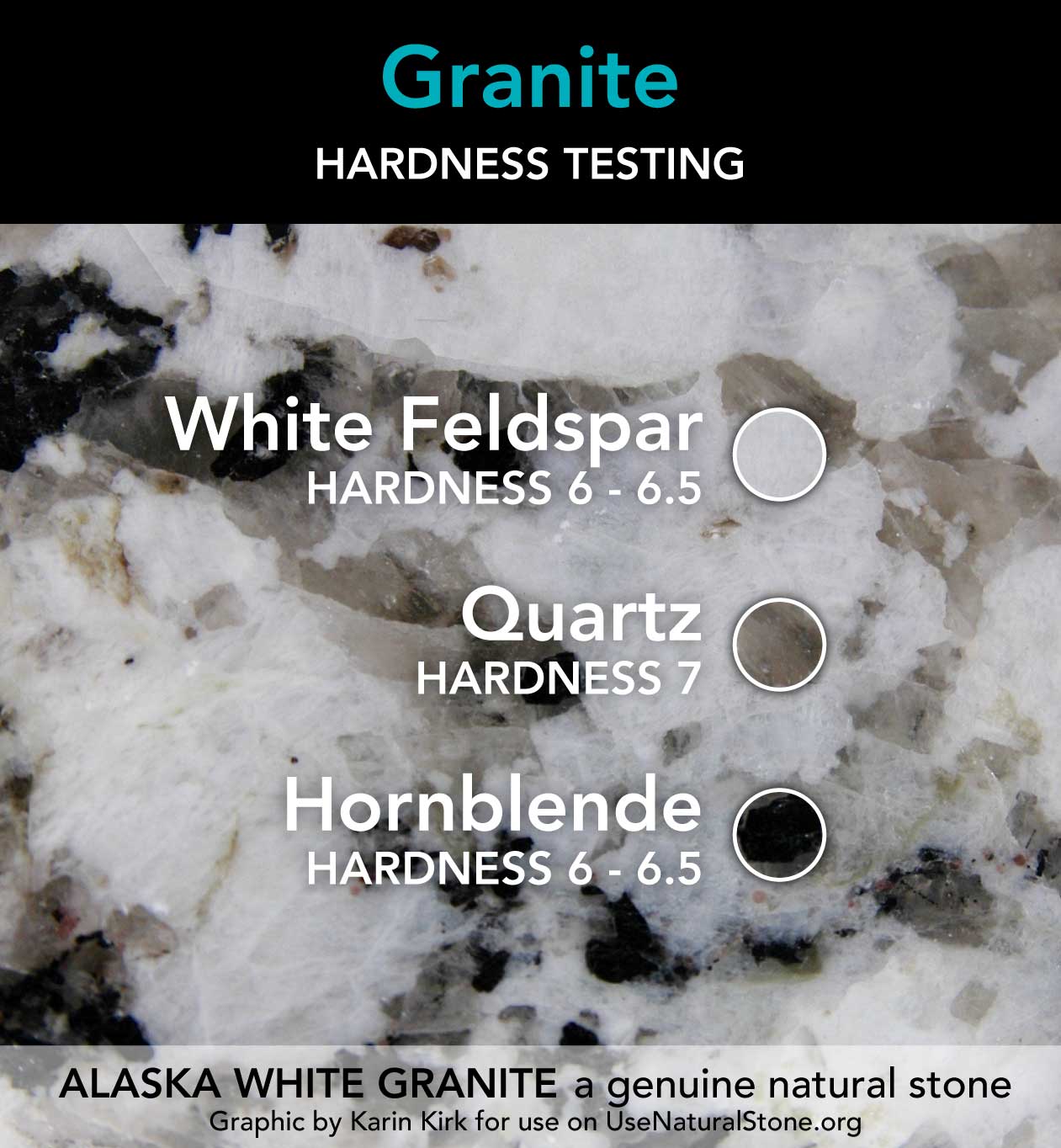

Before we jump into a fact-check on hardness, it’s worth pausing to point out that hardness only relates to a surface’s resistance to being scratched. Hardness has little to do with chipping and nothing to do with staining.

Areas with pools of resin are often the softest part of a manufactured quartz surface. On this sample of Cambria Shirebrook, the resin is lightly scratched by a tool with a Mohs hardness of 6. Image courtesy of Karin Kirk.

Is quartz surfacing much harder than granite? This is straightforward to verify using metal picks calibrated to different hardness on Mohs scale. In test cases where the sample contained large particles of mineral quartz, the individual quartz grains yielded a hardness of 7. The “matrix” material around the larger particles were generally 6 to 7, with some areas between 5 and 6. Larger pools of resin were between 5 and 6. On colors where the particles are uniform and fine-grained, the hardness fell in the range of 6 to 7.

How does that compare to granite? Mineral quartz has a hardness of 7. Feldspar has a hardness of 6 to 6.5. These two minerals make up somewhere between 100% and 90% of a standard commercial granite. Other typical minerals in granite could include hornblende (hardness 5-6), pyroxene (hardness 5-6), biotite (hardness 2.5-3), and garnet (hardness 6.5-8.5).

I analyzed samples from several different quartz manufacturers. The Cambria samples I tested were similar to, or slightly softer than granite. Are they “much harder?” No.

This Caeasarstone sample is scratched by a metal tool that has a Mohs hardness of 6, and this result was repeated on several samples and colors. Therefore the hardness of these samples is less than 6. Caesarstone lists the hardness of their product as 6.5 to 7. Image courtesy of Karin Kirk.

Looking at other brands yielded similar findings. The fine-grained matrix on Caesarstone colors such as Buttermilk, Lagos Blue, and Pebble had a hardness of between 5 and 6, while larger, individual quartz particles in coarse-grained varieties were 7. Pental samples were largely between 6 and 7, with a few spots in the 5-6 range. LG Viatera samples came in right around 6 or slightly less. Silestone Nebula colors were also between 5 and 6.

These results make sense. Particles of quartz are a hardness of 7, regardless of whether they are in a natural stone or a manmade composite. Polyester filler and binder materials are softer than quartz, which is reflected in the softer values in those areas of the slab.

“Dancing a Mighty Fine Line”

Fabricator Dave Scott has been making countertops for 25 years. He works in quartz, natural stone, and sintered ceramic materials and he appreciates the advantages of each. His shop, Slabworks of Montana, serves high-end clients near Big Sky and Yellowstone Club ski resorts, as well as more typical homeowners in the Bozeman area.

“I’m not anti-quartz,” he explained, “but I’m just not a fan of some of their marketing.” In his experience, the biggest drawback of manufactured quartz is the way it can be damaged by heat. “I’ve replaced enough of them; I know,” he said wryly. Electric frying pans and slow cookers are some of the biggest culprits, he added, which can cause quartz surfaces to crack or scorch. Over the course of his career, Scott has seen numerous failures with cook top cutouts, more so than with natural stone slabs.

Scott noted that many quartz manufacturers list the upper end of the proportion of mineral quartz in their products, but they don’t often cite the lower ranges. “They range from the low 80s up to 93% at the top,” he said, while explaining that the solid colors typically have a lower percentage of quartz minerals.

When it comes to the way manufactured quartz companies call their products natural stone, Scott voiced some concerns. “Either you are [natural stone] or you’re not,” he quipped, adding that the claims of manmade quartz companies are “dancing a mighty fine line.”

“They’re trying to compare themselves to natural stone,” said Scott. He motioned out the window to the rows of granite, quartzite, and marble in the yard, adorned by recent snowfall, and continued emphatically, “But these are unique, God-made pieces of art for us to enjoy.”

And therein lies the essential difference between purely natural products versus engineered lookalikes. There can be no doubt that real stone is a product of the Earth, created by geology, God, or whichever combination you prefer. Natural stones are natural, abundant, and fundamental parts of our planet. They bring life and energy into our homes and public spaces and are unquestionably authentic. Amid the confusion wrought by marketing strategies, perhaps the most useful conclusion lies in the age-old adage: Imitation is the sincerest form of flattery.